- Founded in 1949

Your partner of precision forged and finished industrial components

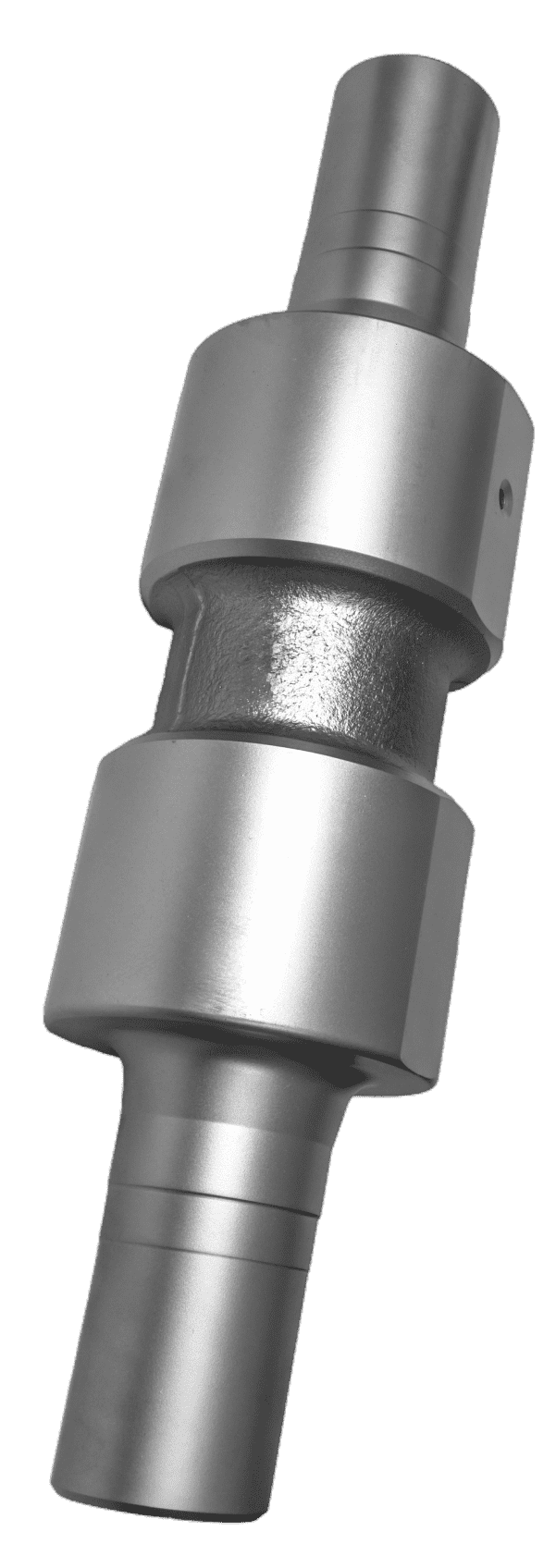

We ensure the highest quality and reliability in forged and finished industrial components streamlining the process from prototypes to finished parts to meet highest customer requirements.

- Processes

BEST PRACTICE FOR ANY PART GEOMETRY

We offer top-tier forging solutions for components from 1 to 60 kg, with in-house heat treatments, deburring, and calibration. Using advanced CAD-CAM tools, we ensure high precision and quality. We’re committed to transparency in our sustainability efforts, inspiring a greener future for industrial components.

R&D Engineering

Our engineering team excels in designing and building proprietary tools and dies using advanced CAD-CAM tools such as Creo Parametric, Powershape, Powermill, Feature CAM, Esprit, and AutoCAD. We also specialize in hot forging simulations to ensure precision and efficiency in our industrial component manufacturing processes.

Hot forging

Heat Treatment

We offer advanced heat treatment services with a continuous automatic heat treatment line capable of processing 1500 kg per hour. Our processes include quenching & tempering and annealing. We handle components ranging from 2 to 60 kgs, ensuring optimal performance and durability.

Machining

We offer comprehensive machining processes including milling, grinding, turning, boring, and threading on advanced CNC machining centers. Our facilities include precision milling and boring centers, with CNC capabilities for parts up to Ø700 x 1500mm and 2150x750x800mm. Our extensive machine park consists of 12 CNC machining centers, accommodating parts from 1 to 2750 kg.

- Products

Sustainable forged components

Enhance your automotive performance with our precision-forged components. Designed for durability and efficiency, our industrial-grade solutions are now developed specifically for the automotive sector.

We provide high-quality components for trucks, skillfully forged and finished to build a legacy of reliability and strength in construction. Our advanced techniques guarantee superior durability and performance, adhering to the most rigorous standards.

We take pride in delivering precision-forged and finished parts designed to endure extreme conditions and meet the rigorous standards of the oil and gas industry.

- Quality assurance

Quality Assurance Driving Industrial Excellence

At Premagro SA, our commitment to quality assurance drives industrial excellence. We implement rigorous quality control processes to ensure our products meet the highest standards of reliability and performance. Through continuous improvement and stringent testing, we guarantee that our forged and finished industrial components consistently deliver superior results.